Advantages of Aluminum Wire Mesh for Aircraft

There are several industrial applications for aluminum wire mesh. They are essential to the manufacturing, construction, agriculture, pharmaceutical, food, and auto industries’ production and processing. In the aircraft sector, aluminum wire mesh has numerous applications as well. Aluminum wire mesh is utilized in many types of aircraft, from commercial to military, and it contributes to aviation safety. There are several advantages of aluminum wire mesh for aircraft.

1) Reduction of Noise

Commercial aircraft must adhere to severe noise control standards. Placing aluminum wire mesh inside the nacelle, which houses the engines, equipment, and fuel, is one method to lessen noise. By channeling the sound of a jet into the engine’s honeycomb section, the delicately woven metal mesh aids in reducing its noise.

2) Contamination Avoidance

A military jet flies swiftly. The usual cause of overhauls on jet engines is pollution. The entry of dirt and debris into the most important systems might result in expensive repairs and early failure. This is avoided by the installation of aluminum wire mesh filters, which can protect the engine from contaminants during flight.

3) Air Quality Management

The quality of the air inside airplanes is crucial to the crew and passengers’ health, safety, and general enjoyment of the flight, much like it is in houses and other structures. The necessity for appropriate filtration is increased when commercial aircraft fly at high altitudes because the air within is typically circulated. Contaminants and other irritants that can cause breathing difficulties can be avoided by using aluminum wire mesh in an airplane’s air filters.

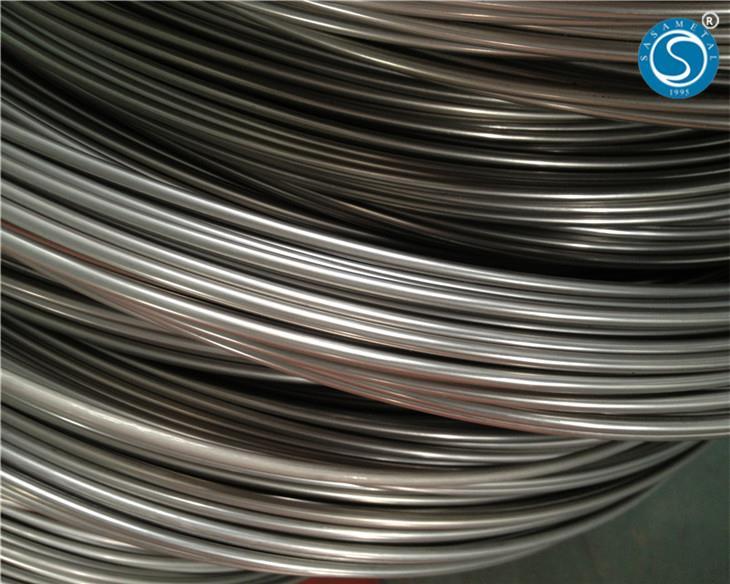

4) Losing Weight

Aluminum wire mesh is used in the aerospace sector to lessen the total weight of aircraft because it weighs only around one-third as much as stainless steel and other metals. Aluminum hardware cloth is frequently used in aircraft nacelles, engines, and air filtration systems. Other forms of metal are rarely utilized inside airplanes since the material is so light. Aluminum mesh can be included in the design of doors, seats, overhead bins, and other useful internal components.

5) Preventing Corrosion

Another benefit of aluminum is that it doesn’t corrode easily. Aircraft need to be able to withstand corrosive environments because they are frequently exposed to high-altitude elements, harsh climates, and high speeds. Intense winds, rainstorms, and cold temperatures can all be mitigated using aluminum wire mesh.

trade-global

trade-global